Infrastructure Management

Energy infrastructure assets require consistent monitoring and maintenance to ensure operational integrity, safety compliance, and maximum uptime. Traditional inspection methods are often dangerous, time-consuming, and limited in scope. Our advanced drone solutions provide comprehensive infrastructure assessments with reduced risk, lower costs, and superior data quality.

Solutions for Infrastructure Management

Structural Integrity Assessment

Our specialized imaging technology provides detailed inspection of critical infrastructure components.

Comprehensive Visual Documentation

We capture high-resolution imagery of all structural elements, including those in difficult-to-access locations

Defect Identification

Advanced image processing detects early signs of corrosion, cracking, deformation, and other structural concerns

Baseline Comparison

Sequential inspections track deterioration over time, enabling data-driven maintenance planning

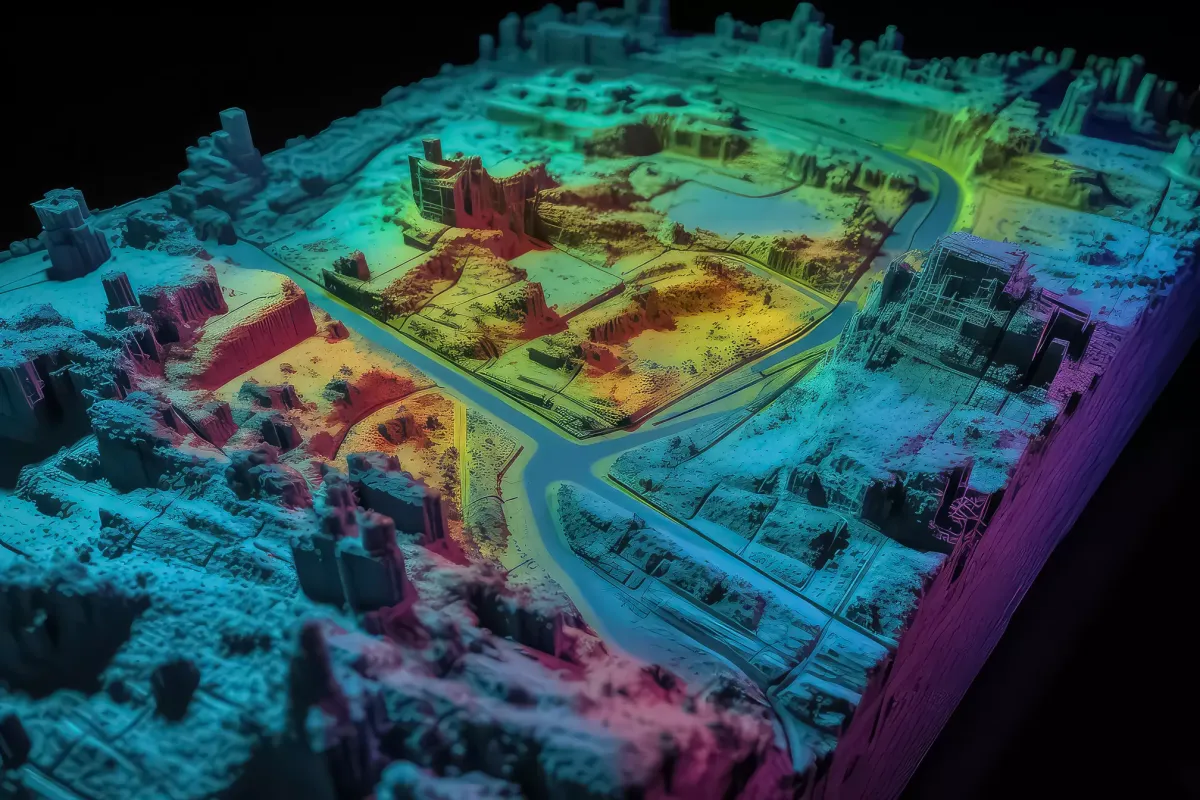

Thermal Performance Analysis

Our advanced thermal imaging solutions identify issues before they lead to failures.

Component Temperature Monitoring

We identify abnormal thermal patterns indicating electrical issues, insulation failures, or mechanical stress

System Efficiency Verification

Comprehensive thermal mapping assesses overall system performance and identifies optimization opportunities

Preventative Maintenance Targeting

Thermal anomalies help prioritize maintenance activities to prevent costly failures

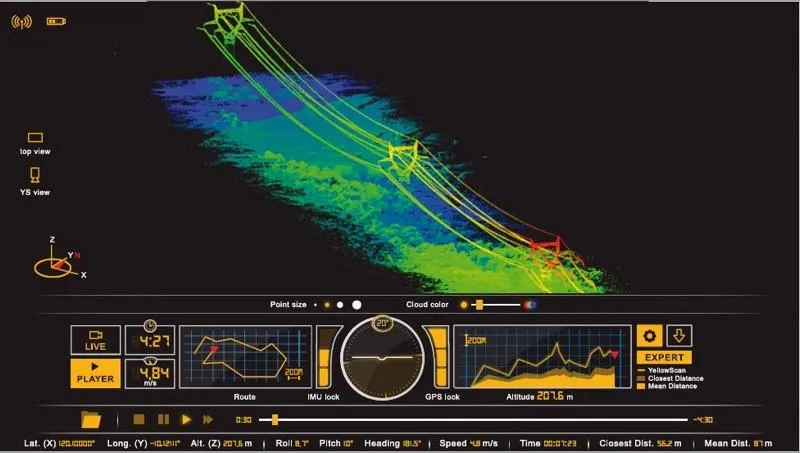

How Our Solutions Work

Advanced Detection Technology

High-Resolution Visual Imaging

Industrial-grade cameras with powerful optical zoom capabilities capture detailed imagery of infrastructure components from safe distances

Thermal Imaging Systems

Specialized thermal sensors detect minute temperature variations that indicate potential issues invisible to the naked eye

Secure Data Management

Cloud-based infrastructure creates a comprehensive digital record of all assets and inspection history

Real-Time Data Processing

Cloud-based processing converts raw data into actionable information within hours instead of weeks

Action-Oriented Deliverables

Digital Asset Management Platform

Centralized repository of all infrastructure components with complete inspection history and maintenance records

Condition Assessment Reports

Detailed documentation of current infrastructure status with prioritized maintenance recommendations

Historical Trend Analysis

Comparative analysis of asset condition over time, enabling predictive maintenance planning

Why Work With Us

25+ Years Experience

in Energy Sector

Part 107 Certified

Drone Pilots

Professional Land Surveyor

(PLS)

OSHA

Safety Trained

How It Works

After you contact our team we will go over all details with you and determine when & where the project will take place. We will also determine what data will be collected & what reports will be sent to you prior to the project.

Our Goal

RidgeIQ aims to offer cost-effective solutions without sacrificing precision or data accuracy. Our expert pilots have been flying UAVs for 10+ years & have all of the field-experience to complete any project you might take on.

© 2025 RidgeIQ. All rights reserved.