Safety Assessment & Risk Mitigation

Safety and risk assessment are paramount in the oil & gas industry, where operational hazards, structural failures, and environmental risks can lead to costly incidents. Traditional safety inspections often require manual fieldwork, placing personnel in hazardous environments while consuming valuable resources. Maintaining safe operations across oil and gas assets requires comprehensive visibility into potential hazards and developing risks before they result in incidents.

Solutions for Safety & Risk Assessment

Facility Safety Assessments

Our inspection capabilities deliver superior hazard identification:

Structural Integrity Evaluation:

Assessment of tanks, vessels, and support structures for signs of compromise or failure points.

Equipment Condition Monitoring:

Identification of damaged components, missing guards, or operational hazards that could lead to incidents.

Fall Protection Verification:

Inspection of railings, ladder cages, and safety equipment at height without putting personnel at risk.

Safety System Assessment:

Verification of fire water systems, emergency equipment, and critical safety infrastructure

Operational Risk Detection

Identify developing operational risks before they escalate into incidents:

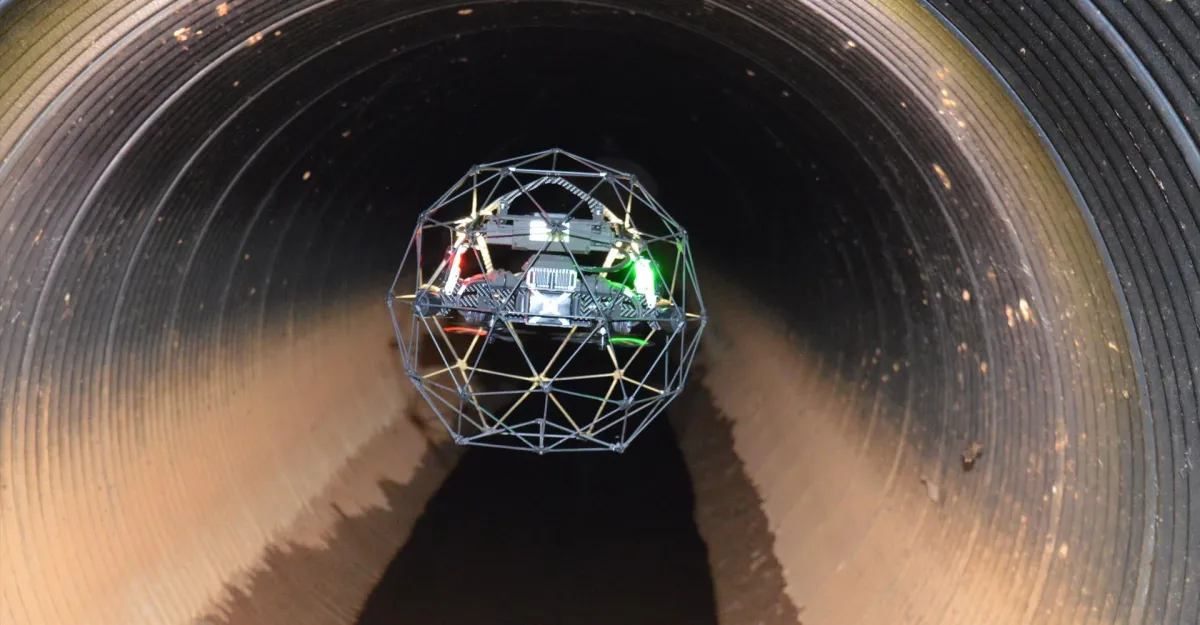

Confined Space Pre-Entry Assessment:

Remote interior inspection of vessels and tanks prior to personnel entry, dramatically reducing exposure to hazardous environments.

Hazardous Material Containment:

Verification of containment system integrity, checking for cracks, deterioration, or design issues that could lead to releases.

Critical Safety System Verification:

Visual confirmation of safety systems including gas detection equipment, pressure relief devices, and emergency shutdown systems.

Regulatory Compliance Advantage

OSHA Process Safety Management (PSM) requirements for equipment integrity and hazard assessment

API Recommended Practices for facility inspection and maintenance

EPA Risk Management Plan (RMP) documentation and hazard analysis

Insurance Carrier requirements for risk reduction and loss prevention

Business Benefits

Most clients see 40-60% cost reduction compared to traditional ground-based OGI surveys

The safety benefits are substantial – eliminating at-height work and confined space entries

Many report significant product savings once systematic detection and repair become routine

The comprehensive documentation provides protective value during regulatory interactions

How Our Solutions Work

Advanced Detection Technology

High-Resolution Imaging:

42MP cameras capture detailed assessment of equipment conditions, from safe distances

Confined Space Specialists:

Our collision-tolerant drones can safely navigate inside tanks, and confined spaces

Thermal Imaging Integration:

We detect overheating equipment, electrical issues, and other invisible hazards

3D Mapping Capability:

Creating comprehensive digital twins of facilities for planning and safety training exercises

Industry Applications

Upstream Operations:

Our drone technology is particularly valuable for remote production locations, offering regular safety oversight without the need for frequent travel to isolated sites. We help operators maintain consistent safety standards across widely distributed assets where regular in-person inspection is challenging.

Midstream Facilities:

Compressor stations, meter sites, and pipeline rights-of-way benefit from our comprehensive visual assessment capabilities. We're particularly effective at identifying encroachment issues, unauthorized excavation, and equipment deterioration before it impacts operational integrity.

Downstream Operations:

Complex process facilities with extensive vertical infrastructure see significant value in our ability to inspect elevated equipment without scaffolding or production interruption. Our thermal capabilities have proven especially valuable for identifying electrical issues and overheating equipment.

Why Work With RidgeIQ

Lean-Six Sigma

Black Belt

Part 107 Certified

Drone Pilots

Professional Land Surveyor

(PLS)

OSHA

Safety Trained

How It Works

After you contact our team we will go over all details with you and determine when & where the project will take place. We will also determine what data will be collected & what reports will be sent to you prior to the project.

Our Goal

RidgeIQ aims to offer cost-effective solutions without sacrificing precision or data accuracy. Our expert pilots have been flying UAVs for 10+ years & have all of the field-experience to complete any project you might take on.

© 2025 RidgeIQ. All rights reserved.